LC/MS Instrument Qualification

Whether you require basic qualification services or something more complex, our highly experienced teams will be able to advise you on best practices and provide you with the compliance services you require. Speak to one of our specialists to find out more what we can offer for mass spectrometry instrument qualification and validation.

MS Vision provides multi-vendor compliance services comprising of IQ/OQ/PQ procedures, available to support your particular instrument configuration.

Working in a GLP environment is complex enough; our specialists can help you save valuable time in meeting compliance to regulatory demands of FDA and ISO standards.

Instrument qualification is a critical issue in GxP environments or when operating under ISO 17025 or ISO 15189. Our specialists have established procedures available for many instruments which we are happy to discuss with you. Please keep in mind: the qualification and validation process is owned by you! We can only suggest procedures for this which are proven and established, but in the end you have to decide which procedures and criteria show that your instrument is fit for purpose. Therefore every qualification of an LC/MS system is something which needs to be discussed individually. Our starting point for this is typically the established IQ/OQ procedures of the manufacturers.

Please be aware that we cannot offer software validation! Software validation can only be offered by the manufacturer of the software, not ba anybody else. or

Is MS Vision allowed and capable to perform instrument qualifications?

GLP (Good Laboratory Practice) regulations emphasize data integrity, reliability, and traceability of results, which are directly impacted by the quality of equipment maintenance. By regular internal trainings, MS Vision ensures that service engineers possess the specific knowledge and skills to maintain equipment according to the manufacturer’s specifications, minimizing the risk of errors and maintaining data integrity. We can ensure the same level of experience and training as manufacturer trained service engineers and most of our service engineers came directly from the manufacturers to us anyway.

Here’s why proper training is crucial in a GLP setting:

- Equipment Expertise:

Our well trained engineers are experts in the specific equipment, understanding its design, functionality, and potential issues. We have dedicated LC/MS engineers per manufacturer to ensure they know the ins and outs of the mass spec instruments and frequently an engineer is even specialized on a specific class of instruments, e.g. triple quadrupole instruments.

- Proper Maintenance:

MS Vision can perform maintenance and repairs of LC-MS systems and mass spectrometers according to the manufacturer’s recommendations, ensuring optimal performance and minimizing the risk of malfunctions that could compromise data. While we have our own maintenance protocols, these protocols are almost identical to the manufacturers protocols.

- Compliance with GLP:

Properly maintained equipment is essential for generating reliable and traceable data, which is a cornerstone of GLP.

- Documentation:

MS Vision provides detailed documentation of service and maintenance, which is vital for demonstrating compliance with GLP requirements. We also offer full OQ/PV services for many of the mass spec and HPLC instruments we support.

- Reduced Risk:

By using properly trained engineers, laboratories can minimize the risk of errors and deviations from established procedures, ultimately enhancing data integrity.

In conclusion, it is strongly advised to use well trained, specialized service engineers in a GLP environment to ensure equipment reliability, data integrity, and compliance with GLP principles. But the usage of manufacturer-trained serivce engineers is not mandatory accomplish this! At MS Vision, our experienced service engineers meet this criterium as well and we proudly serve the LC-MS groups of many pharmaceutical customers in Europe!

Why have an MS Vision engineer perform your OQ/PV?

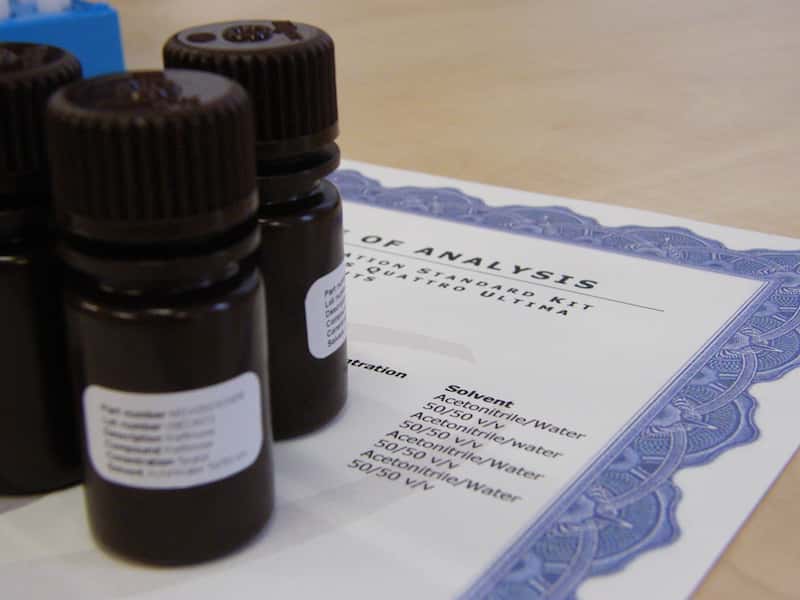

Instrument qualification services performed by MS Vision provide you with a comprehensive documentation solution that includes rigorously tested protocols executed by our experienced field service engineers. These services feature:

- Experienced technical support — our trained service engineers have in-depth knowledge of the platforms we support. All service engineers participated in rigorous technical training either by the manufacturers or in our own facilities, and receive field support from seniour engineers in our company as well as in-depth knowledge from our R&D team. When your instruments are serviced by our certified engineers, you’ll gain confidence and peace of mind knowing that the work is performed to the individual manufacturers instrument specifications.

- Helps increase uptime — our experienced service engineers are available and ready and trained to perform qualification protocols developed for your instrument. Qualification services help reduce laboratory start-up time (or downtime after repairs or scheduled maintenance) so that your lab can get back into operation without unnecessary delays.

- Cost-effective compliance — our qualification services are a predictable expense for your laboratory, reducing development and verification time and costs associated with burdening in-house technical resources to document instrument performance.

Select The Instrument Qualification Level:

Installation Qualification (IQ):

Required for new instruments, or pre-owned but installed for the first time at your facility. IQ is usually carried out together with OQ as IQ/OQ.

The installation specification measurements are a typical example of an IQ and an IQ is usually performed according to manufacturer specifications

Operational Qualification (OQ):

The OQ verifies and records instrument’s ability to meet the specified operational criteria after an installation, following repetitive use or after major service interventions

Performance Verification (PV):

PV (also known as Performance Qualification or PQ) is a customer defined performance protocol that is run on your complete (U)HPLC/MS system configuration. The protocol is run following any service intervention, saves valuable analyst time and leaves your complete instrument ready to run samples. Protocols for PV need to be supplied by the customer and agreed by both parties before the service.

MS Vision can help you with your lab’s compliance needs from purchase/installation after relocation all throughout the equipment’s life cycle:

This is a general recommendation from MS Vision for all LC/MS lab equipment used in a regulated environment. Labs should adapt the frequency of requalification and performance tests based on the recommendations of their quality team and equipment’s risk assessment. Installation qualification is commonly done by the manufacturer a spart oft he installation process and calibrations are normal part of the preventive maintenance. However, especially time-of-flight mass spectrometry instruments require much more frequent recalibrations depending on the environment. But this can be as frequent as several times a day to ensure proper mass accuracy. Quadrupole and Orbitrap based instruments are less sensitive regarding mass shifts.

Multi-vendor compliance services

MS Vision compliance services are unique due to our in-depth know-how and support of multiple brand instruments.

We offer qualification services for

- Waters Single- and Triple Quad systems (ZQD, SQD(2), QDa, Quattro and Xevo series)

- Waters TOF- and QTOF-systems (QTOF, Xevo and Synapt series)

- Sciex Triple Quad and QTrap systems (4000 and Blueline [45/55/6500])

- Sciex QTOF-systems (5600, 6600)

- ThermoFisher Triple Quad, Ion trap and Orbitrap systems