Sustainability is not only a word for us at MS Vision. We hate throwing away well working instruments and we genuinely believe that many instruments can be upgraded to achieve new performance heights.

When you purchase a mass spectrometer, this is usually a longer term investment of several hundred thousand Euros or Dollars. Yet after a couple of years, you might not need this instrument anymore as the research project had ended or you were able to replace it by a newer model.

Sometimes you also need another system to increase capacity, but the existing model does the job well. Thus you won’t need the newest gadget but just anything fit for purpose.

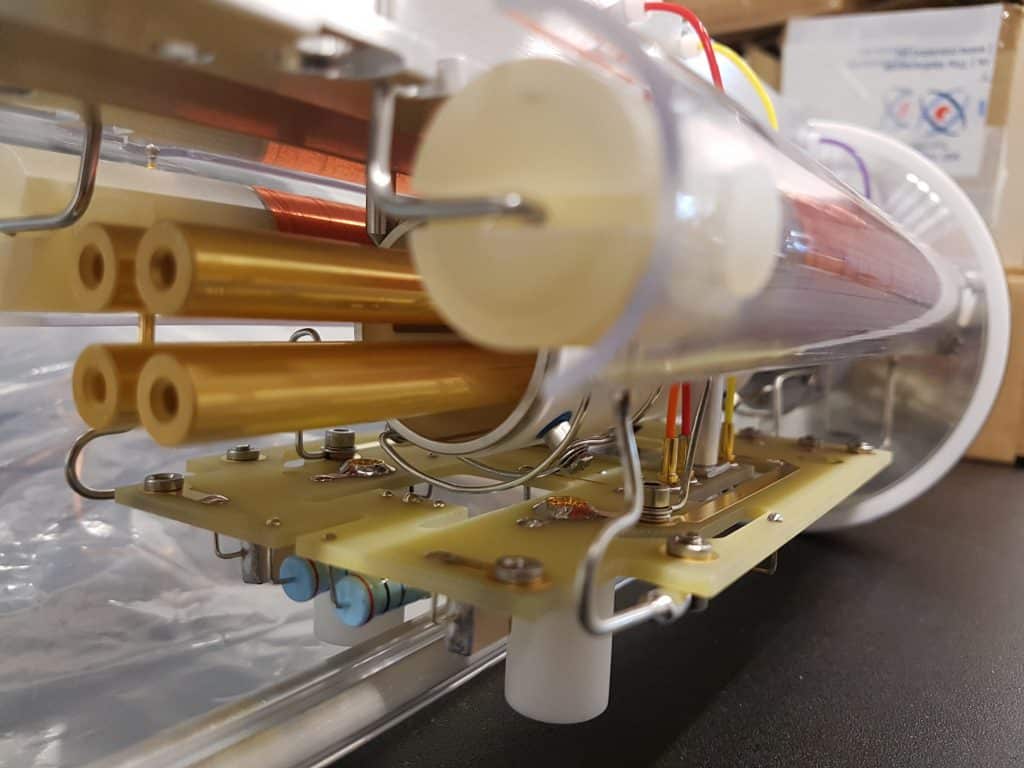

These are typical cases whereMS Vision can help. We buy and sell refurbished pre-owned mass spectrometers. This can save you money and help you to achieve a better return on investment in a commercial setup.

Scrapping a mass spectrometer is a huge waste of resources. A typical mass spec weighs around 100-500 kg and contains large amounts of aluminium alloys and electronics components with gold, nickel, cobalt, rare earths and other valuable resources. The stainless steel parts are often alloys containing chrome, vanadium and molybdenum. Some of these elements contribute significantly to environmental contaminations and should be used as efficiently as possible.

But this is not all we do! We also upgrade existing instruments, either yours on site or one from our stock, to boost their performance and let the achieve things you would not have assumed before.

Do you think a 20 year old LCT premier can achieve what a QExactive UHMR can? Well, it can, and to some extend at even higher performance!

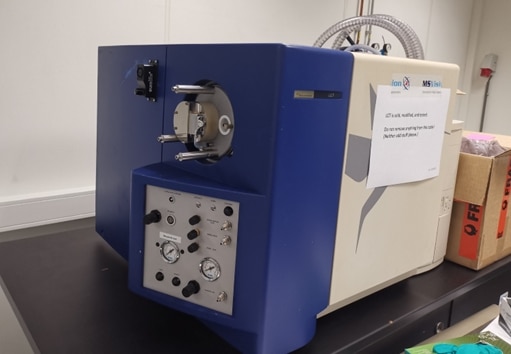

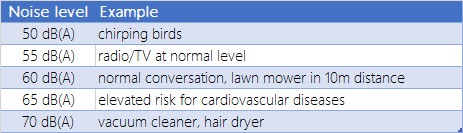

A Micromass LCT premier was upgraded to a High Mass ESI-TOF system with several modifications in the source and transfer region.

This enables the instrument to easily detect non-covalent complexes into the several 100kDa mass range.

Currently, MS Vision offers upgrades for Waters QTOF and Synapt instruments as well as for ThermoFisher QExactive plus systems.

High mass upgrades are available for all types of instruments, the combination of optical spectroscopy and IM-MS is only available on the Synapt platform.

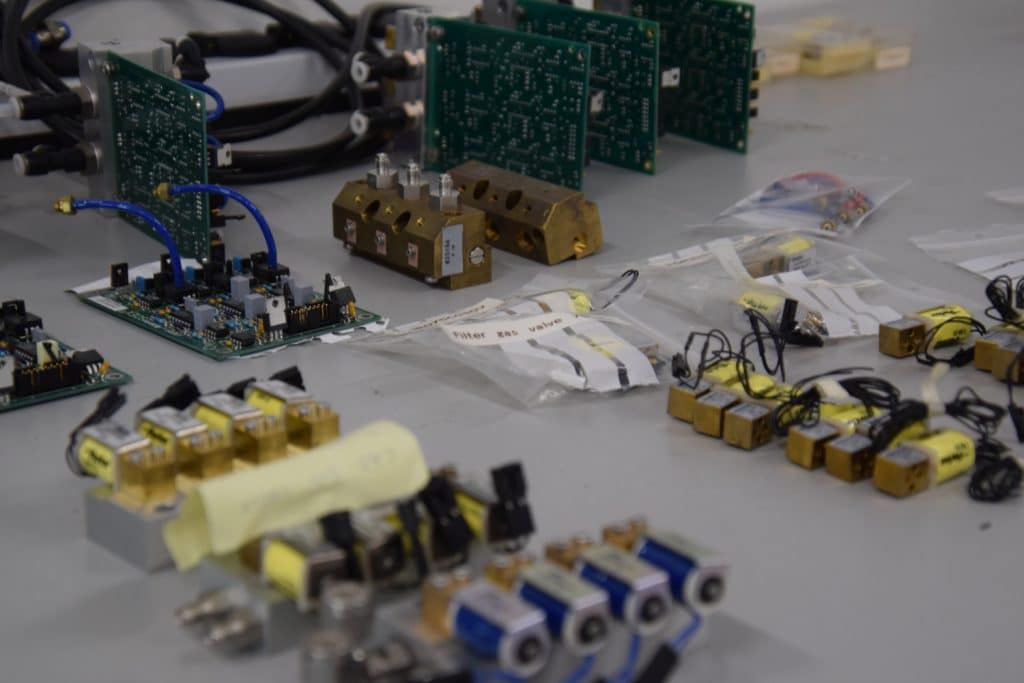

But we do not stop there. We keep tested parts from pre-owned instruments on stock when the instrument is scrapped to ensure a long lasting supply of parts. E.g. we have a significant stock of Waters embedded PC’s which only work with a specific, out-of-production computer hardware. With these parts we are able to provide support long after the end-of.-service lifetime of many manufacturers and also can significantly save costs as parts for out-of-service instruments tend to increase in price significantly faster then more modern spare parts due to their limited availability.

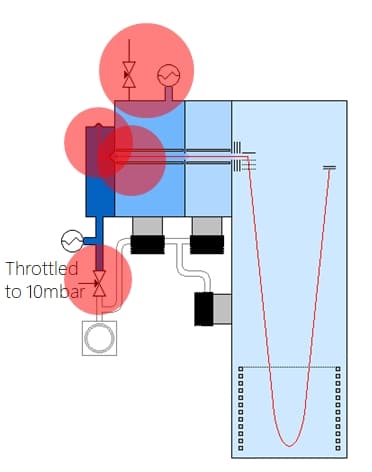

We also think about ways to reduce energy consumption on mass spec systems. The systems are permanently under high vacuum and that needs consistent pumping. Most of the pumping with LC-MS systems is required in the source area where the transition from ambient pressure to high vacuum takes place.

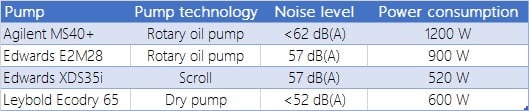

Choosing the right pumps can significantly reduce your power bill as well as the noise level in your lab. E.g. Edwards XDS35i scroll pumps have around 40% of the maximum power consumption of an Agilent MS40+ pump, a Leybold Ecodry 65 has half of the power consumption! In addition to the lower power consumption, these pumps also produce less heat which in return reduces the energy required for air conditioning.

What would you think how much this is? Let’s assume we can save 1 kW/h (corresponding to the power uptake of two pumps which is not converted into heat). An air conditioning system needs about 1/3 of the energy to get rid of the 1kW heat energy, so 330 W/h. 24 h a day, 365 days a year. That sums up to 2890 kWh per year, the energy consumption of a typical 2 person household and corresponds to costs of around 840€ p.a. (at a cost of 29 cents/kWh, which is EU average as of 2024).

Another way to significantly reduce power costs is to shut the source valves on LC-MS instruments when they are not in use. This not only avoids contamination with material in the ambient air such as ubiquitous plasticizers, but also reduces the workload on the pumps. Our R&D scientists have calculated that for Synapt or QExactive this can save up to 1.1 tons of carbon dioxide a year!

A point often underestimated is the noise level created by the pumps. Not in general, I think all of us in mass spectrometry are aware of the extreme noise levels in a mass spec lab. But we usually underestimate what difference a change may make.

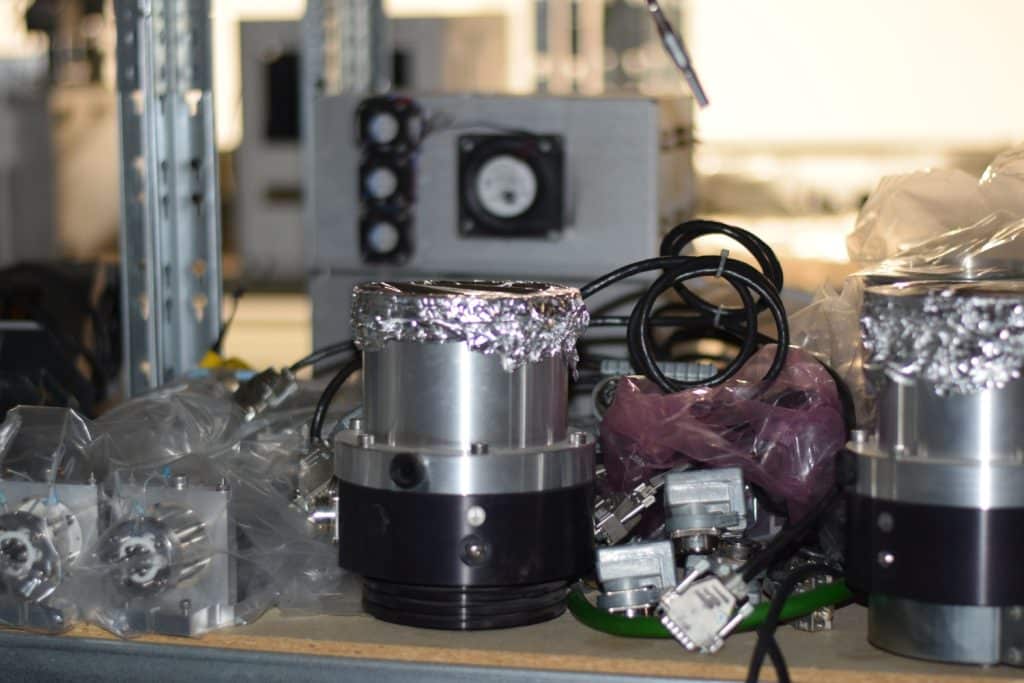

Various pumps have significantly different noise levels. While older pump types as rotary vane pumps and scroll pumps are in the range between 55 and 65 dB(A), newer dry pumps are more in the range of 50 to 55 dB(A). That doesn’t sound a lot, but keep in mind that dB(A) is a logarithmic scale! 60 dB(A) is twice as loud as 50 dB(A) and 65 dB(A) already poses an elevated risk for cardiovascular diseases. So, when a pump is defect, consider a change to a newer technology for reduced power consumption and a more quiet lab environment! If you don’t know which pumps could be used in exchange of an older model, ask us!

To continuously improve in terms of sustainability, MS Vision also regularly participates e.g. in the “Sustainability in MS Workshop” organized by the British Mass Spectromtery Society, e.g. with a presentation by Steve Daly on upgrading and recycling existing instrument.

In addition, MS Vision participates in certification programs such as Integrity Next to monitor and improve our environmental footprint.

How to become more sustainable in LC-MS?

Apart from the instrument hardware, there are always ways to become more sustainable (and to save money on consumables and reagents at the same time) in LC-MS. The easiest way is to reduce the flow rate for your LC. Many people now think about nanoLC, which can give you incredible sensitivity and is the method of choice in proteomics applications due to available sample amount limitations.

However, for routine applications, nano LC would not be our recommendation for several reasons:

- the run times of nanoLC gradients is very long, often in the range of one hour or more. This is not only due to sample complexity but primarily due to column equilibration. Column equilibration is calculated by volume and at 200 nL/min it will just take “ages”.

- you need dedicated LC hardware. A conventional LC is not capable of generating a reproducible nano flow in the range of 50-250 nL/min. At least, you would need a flow splitter and a dedicated nanoESI-source as also conventional sources will not work with nanoESI spray. This means an investment of 10-20k€.

- instruments operation in nanoESI are prone to faster contamination. It sounds counterintuitive as the flow and the injected sample amounts are low, yet the spray is directed directly towards the orifice. Everything goes into the instrument unlike with the “normal” orthogonal spray of high flow sources. This will cause more frequent cleaning and on some instruments requires frequent deep cleaning.

- nanoESI emitters are prone to clogging to to very small orifices. This can be a real nuisance and is a serious issue in routine operation.

So, what to do? The answer is microLC or capLC! Here you operate at flow rates between 5 and 200 µL/min which often can still be handled by your existing LC hardware and most ESI sources can handle flows down to 2-5 µL/min. Thus investment is essentially the new column. But what can you gain from it?

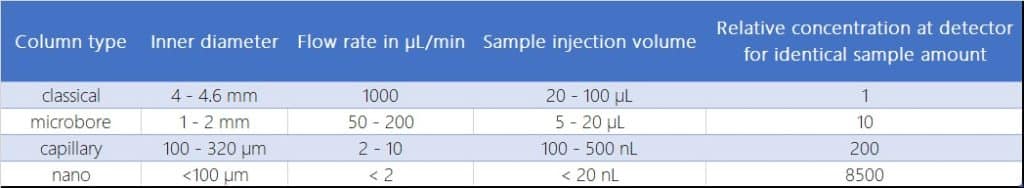

What is often overlooked is that sensitivity in ESI is not determined by sample amount, but by sample concentration! The following table summarizes different LC regimes, the applied conditions and the relative concentration at the detector:

This means that by just going from the conventional 4 mm columns to a 300 micron column will give you around 200 times more sensitivity allowing you to reduce sample consumption and also to reduce solvent consumption by 100 times! Assuming cost of ~100€/L for LC/MS grade acetonitrile and around 40% acetonitrile concentration in average, this will reduce the cost per LC and day by around 55€ plus disposal costs.

Another advantage of capLC is that it does not cost you more time unlike nanoLC. Thus your methods are easily transferable.

So, in summary, the advantages of capLC for routine applications in LC/MS are:

- up to 200 times higher sensitivity

- up to 100 times less solvent consumption

- no increased time for LC methods, fast column equilibration

- almost no changes in LC hardware (only new columns but that’s a consumable anyway)

When do you switch to lower bore columns and send you old gun barrels into retirement?